Featured Case Study

Polton St Care Home

Bonnyrigg

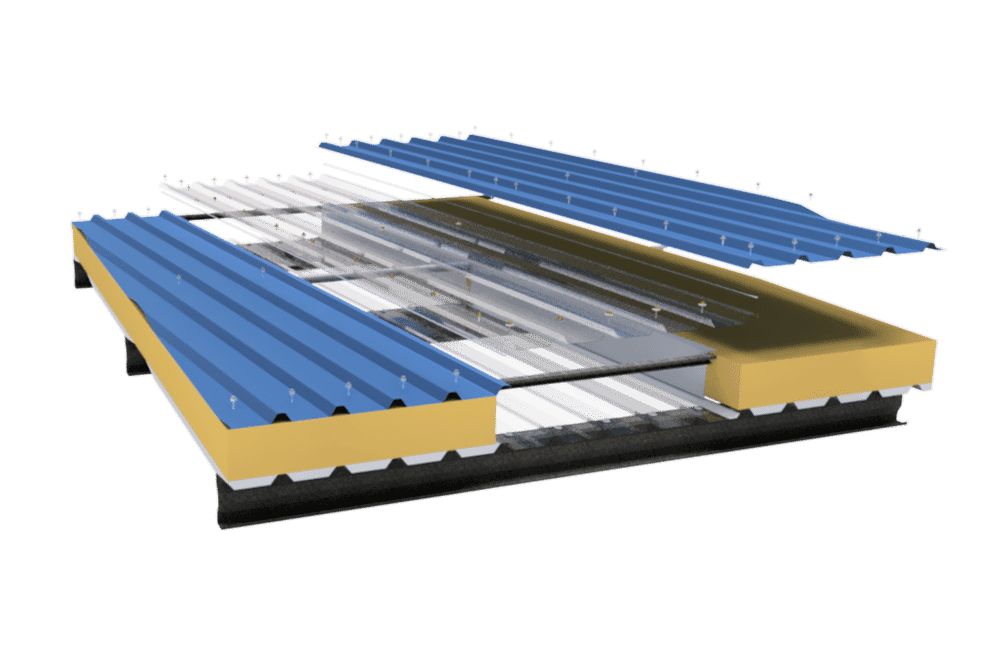

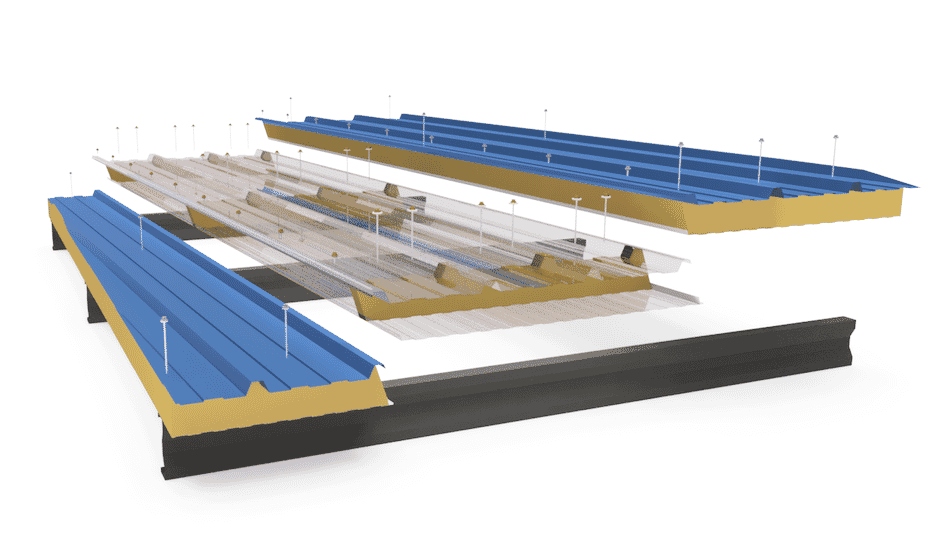

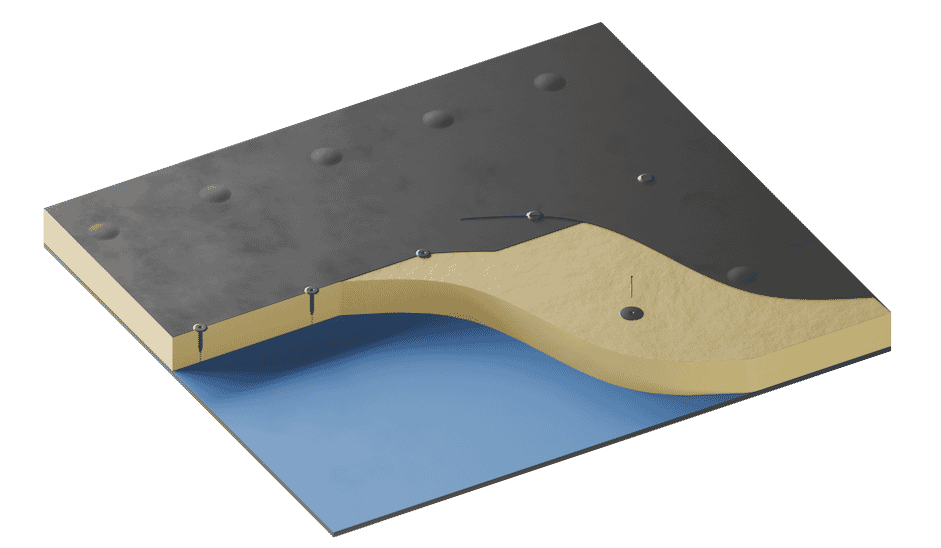

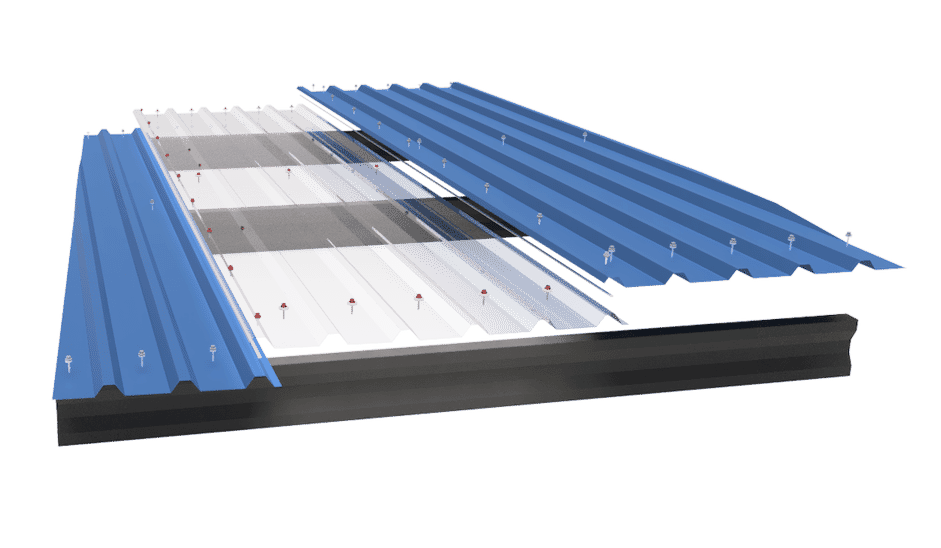

Fixing Point supplied a complete flat roofing solution for a new care home development in Bonnyrigg. The project required durable and fire-safe roofing suitable for Scotland’s challenging winter conditions.

Filter by