Technical services

Technical expertise you can trust.

Our experienced team combines decades of industry expertise with the latest technology to deliver precision-engineered components that fit seamlessly into your project. From in-house technical calculations to advanced injection moulding, we help you secure and seal your building envelope with confidence.

In-house calculations.

We offer a range of technical in-house calculations and testing services to guarantee every component meets your roofing and cladding requirements. Our comprehensive technical calculations include:

- Wind load calculations following UK National Annex to BS EN 1991-1-4.

- Gridtite® system capacity calculations for bracket and rail centres.

- Fastener frequency assessments based on pull-out and pull-through values.

- U-value calculations to improve your building’s thermal efficiency.

- Bespoke calculations for any other project-specific requirements.

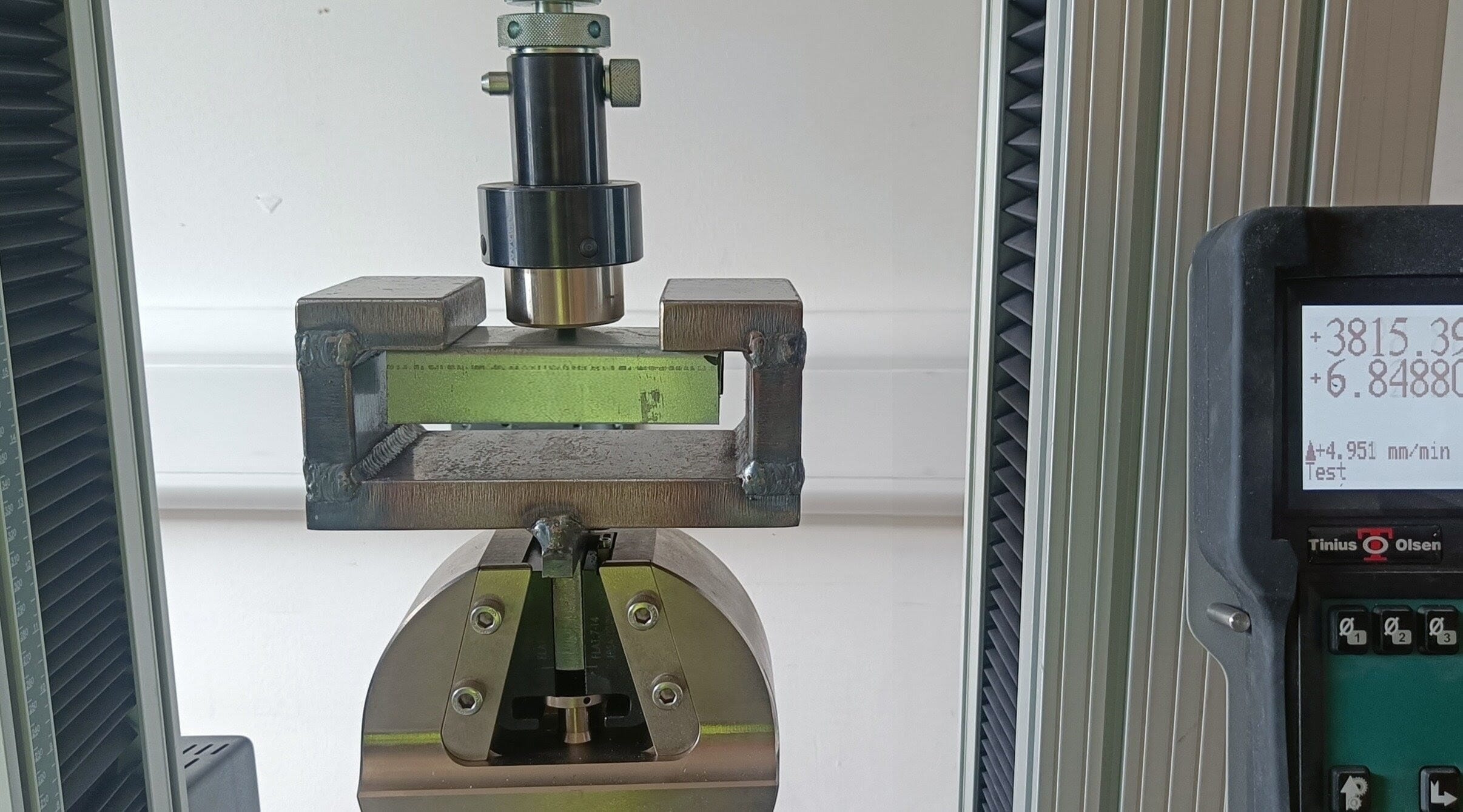

In-house testing.

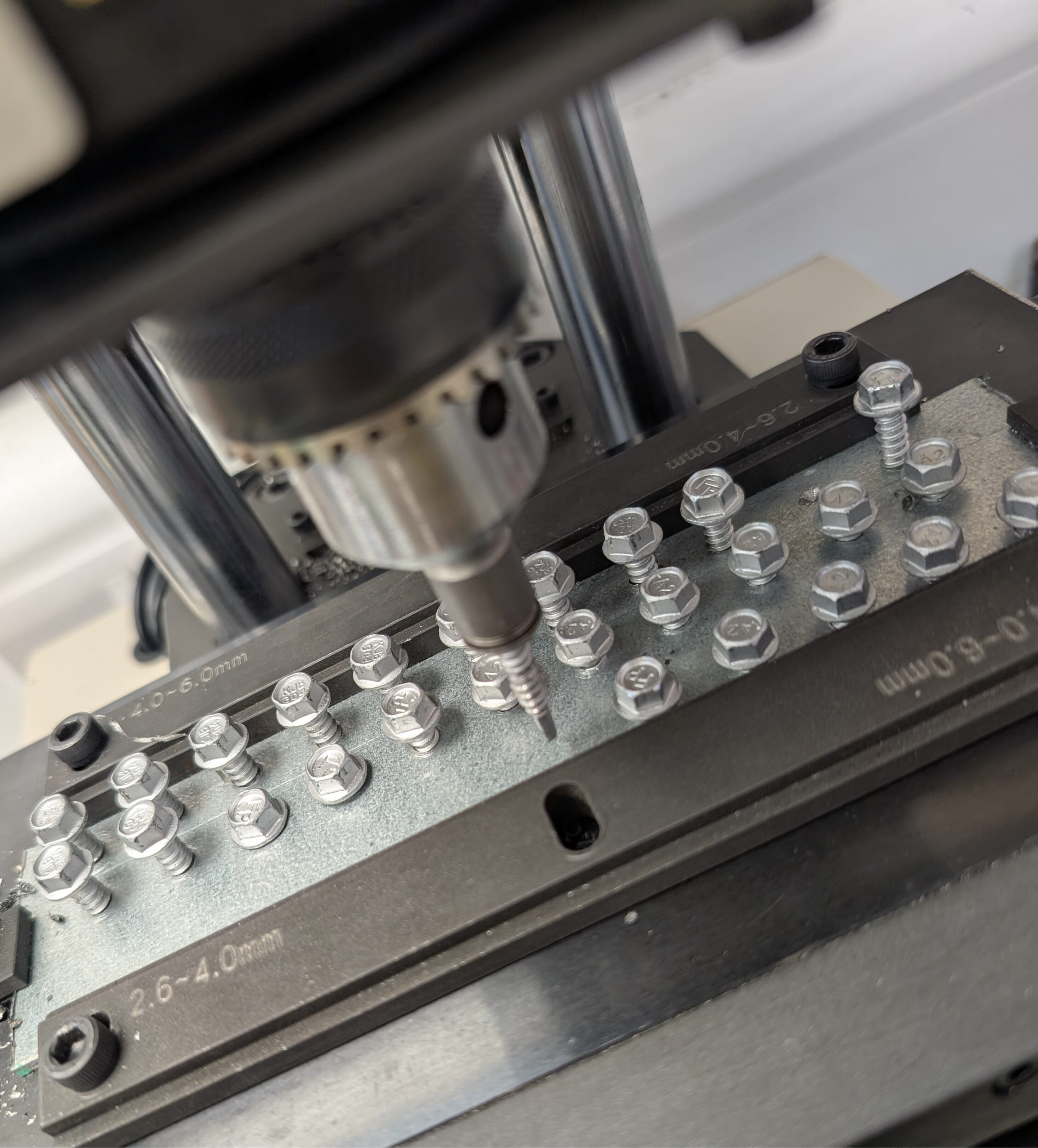

We’ve also invested in a new-generation testing lab with an advanced Tinius Olsen tensile test frame and drill time test machine to validate product performance under real-world conditions. This enables us to provide the following technical testing services:

- Pull-out, pull-through, shear, and tensile testing to evaluate fixing strength.

- Compression and uplift testing for our Gridtite® Spacer Support Systems.

- Drilling and torque tension tests to determine the best drilling speed and torque settings.

- Digital torque analysis to assess injection-moulded head slip and fastener torque-to-strip.

- Paint and material coating analysis with our coating thickness gauge.

Driving innovation in manufacturing.

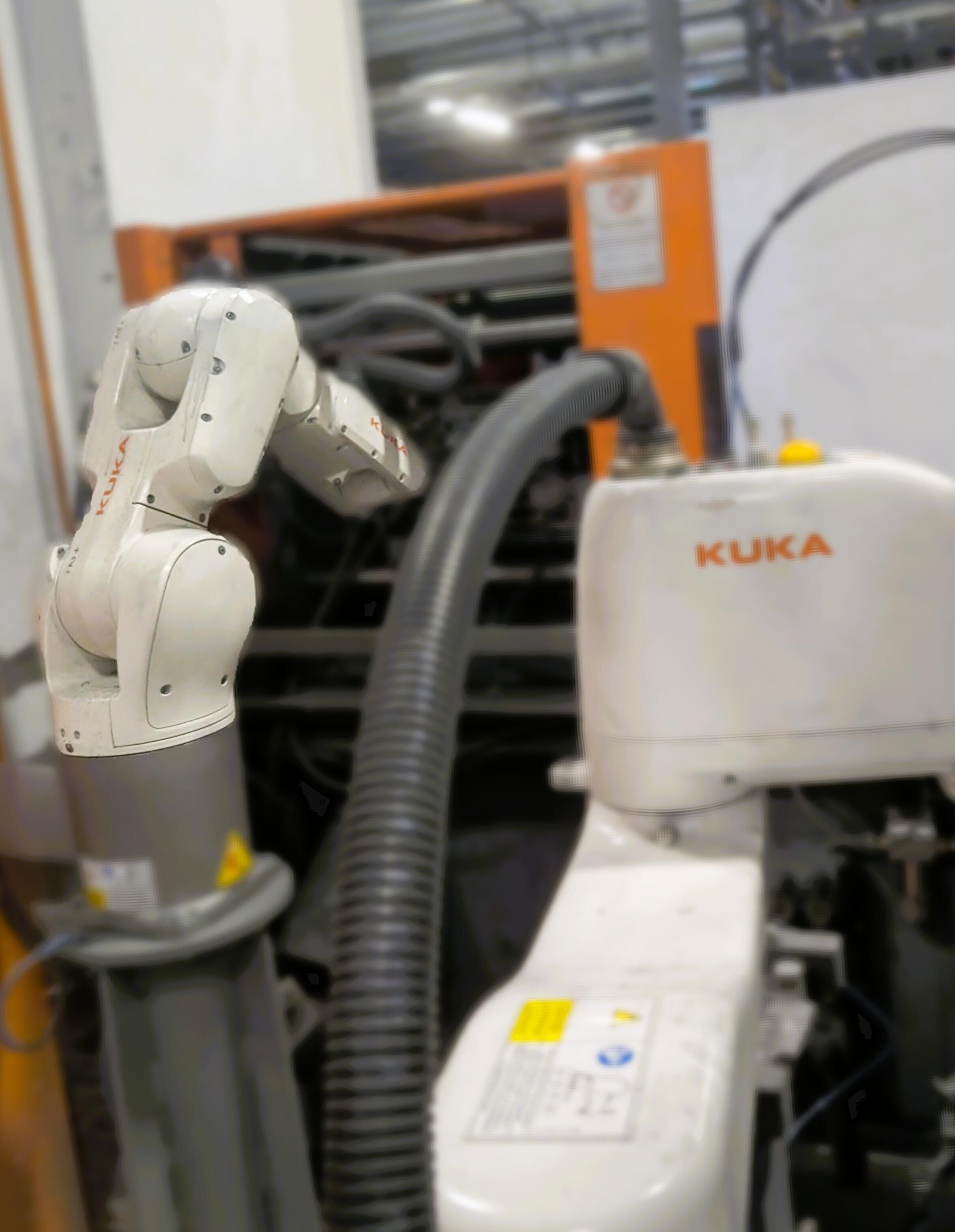

Our ISO 9001-certified production process involves customisation with powder coating (150+ colours available) and injection moulding of our moulded heads (100+ colours available), followed by washer assembly. Orders are then processed and fulfilled using automated warehouse systems, which helps to reduce errors and allows for real-time product tracking. Each stage is carefully controlled for quality and performance, ensuring a seamless solution every time.

Beyond industry standards.

Approved by all of the key OEM’s in the UK market, our fasteners don’t just meet industry standards – they exceed them. We believe in continuous research and development to refine our products and in-house processes. Our active involvement with key industry trade bodies like the MCRMA, NFRC, and SPRA allows us to stay ahead of the latest technical developments and develop new, innovative solutions for the industry.

Our entire range of FP+ stainless steel fasteners are assessed to European Technical Assessment (ETA), ensuring they meet the highest European standards for safety, performance, and durability. This certification provides contractors and specifiers with complete confidence that FP+ fixings deliver superior reliability and compliance for roofing and cladding applications across the UK and Europe. Get in touch for more information about our FP+ range.

Technical datasheets.

Not sure which components are right for your application? Our expert technical team brings over 150+ years’ combined experience and in-depth industry knowledge to every project. From troubleshooting site-specific challenges to optimising fixing patterns for superior performance, our specialists deliver precise, tailored solutions for builds of all sizes and scales.